Larger PCB Board for Battery Packs: Simplified Connections

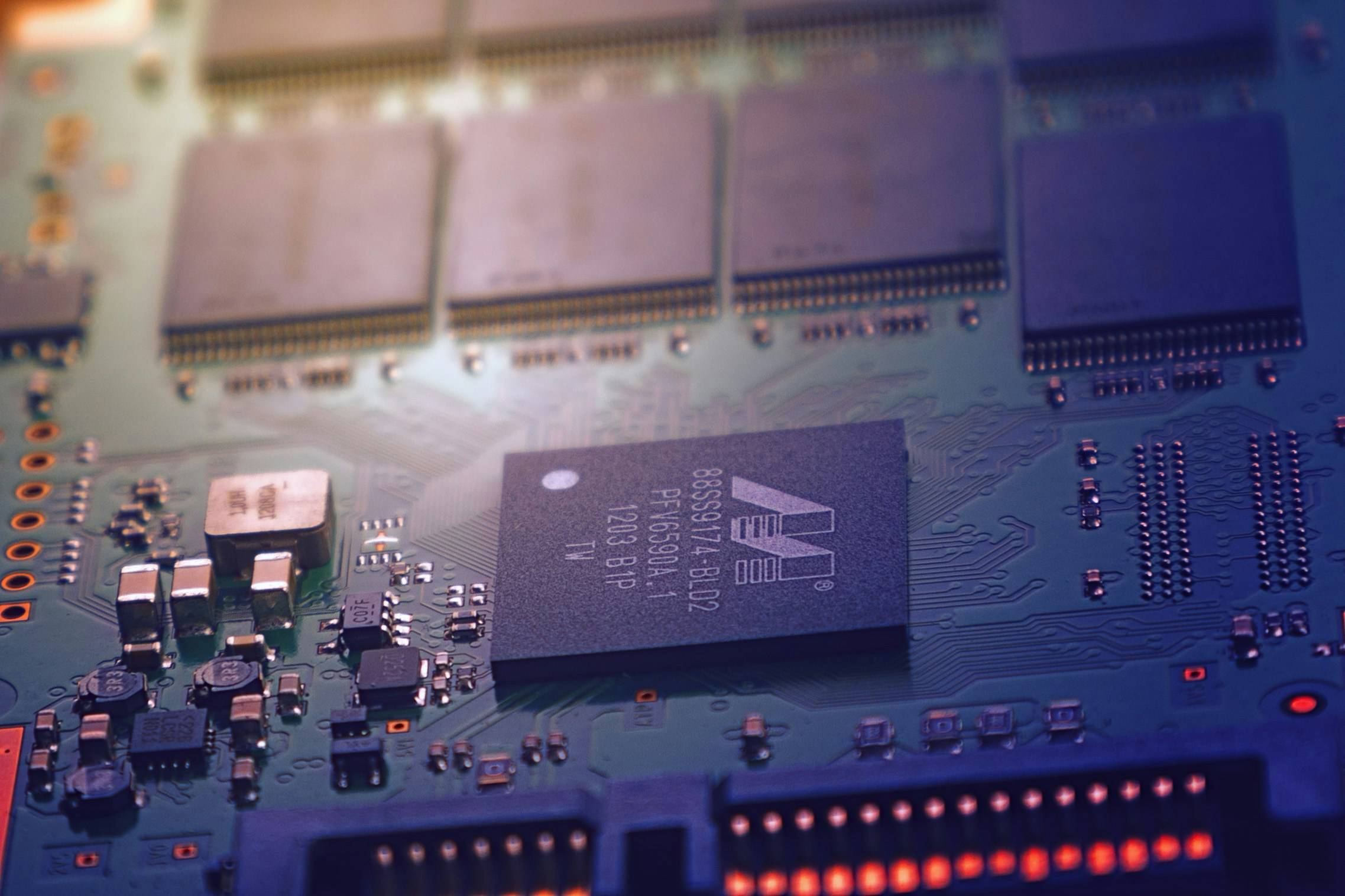

1. Introducing the Larger PCB Board

The stacking method mentioned is effective. However, there is an easier way to build larger battery packs. You can use a specially designed larger PCB board. This board simplifies the process of connecting multiple 4S modules and integrating a BMS.

1.1. Advantages of the Larger Board

The larger PCB board offers several advantages over the traditional stacking method:

Simplified connections: The board has built-in traces that connect the modules in parallel. This removes the need for many cables and connectors.

1. Better current handling: The board's design lets it manage higher currents. This makes it good for high-power uses.

2. Easier assembly: The board provides a single platform for mounting multiple modules, reducing the complexity of the build process.

3. Better heat management: The bigger surface area of the board helps with heat dissipation. This can improve the performance and lifespan of the battery pack.

1.2. Design Features

Let's take a closer look at the design features of this larger PCB board:

1. Multiple module slots: The board has designated areas for mounting several 4S modules, typically arranged in a grid pattern.

2. High-current traces: The PCB has thick copper traces that can handle high currents. These currents can reach 100 amps or more.

3. Dual output connectors: The board usually has two output connectors. Each one can handle about 50 amps continuously.

4. Mounting holes: The board includes mounting holes for securing the modules and for attaching the board to an enclosure or frame.

5. BMS integration: Some versions of these boards may allow for direct mounting of a BMS. This makes the build process easier.

2. Step-by-Step Guide to Building a Battery Pack

Now that we know the larger PCB board, let's go through how to build a battery pack. We will use this board and several 4S modules.

2.1. Preparing the Stacks

Before assembling the battery pack, you'll need to prepare your 4S module stacks. Here's how:

1. Decide on the capacity you need and determine the number of modules required.

2. Group your modules into stacks. A typical configuration might be four stacks of four modules each.

3. Use appropriate length standoffs (usually 30mm) to create space between the modules in each stack.

4. Ensure all modules in a stack are securely fastened together.

2.2. Assembling the Stacks

With your module stacks prepared, it's time to assemble them onto the larger PCB board:

1. Place the first stack onto the board, aligning the mounting holes with the holes on the PCB.

2. Insert screws or standoffs through the mounting holes to secure the stack to the board.

3. Repeat this process for each subsequent stack, ensuring they're all properly aligned and secured.

4. Double-check that all connections are tight and that no modules are loose.

2.3. Adding Ribbon Cables

The final step in the physical assembly is connecting the modules to the board using ribbon cables:

1. Start with the topmost module in each stack.

2. Carefully plug the ribbon cable from the module into the corresponding connector on the PCB board.

3. Work your way down each stack, connecting all modules to the board.

4. Ensure that the ribbon cables are not twisted or strained, as this could lead to connection issues.

3. Important Considerations

When you build your battery pack, remember a few important factors. These will help ensure safety, performance, and longevity.

3.1. Balancing Voltages

Ensuring that all battery modules have the same voltage before putting them together is important. This is a key step in building a multi-module battery pack. Here's why this is important and how to do it:

1. Importance: Modules with very different voltages can create imbalances in the pack. This can lead to poor performance, a shorter lifespan, and possible safety problems.

2. How to check: Use a multimeter to measure the voltage of each module before assembly.

3. Target voltage: Ideally, all modules should be within 0.1V of each other. For example, if one module reads 13.37V, all others should be between 13.27V and 13.47V.

4. Balancing process: If you find modules with voltages that are too high or too low, charge or discharge them separately. Do this before adding them to the pack.

3.2. Safety Precautions

Building battery packs involves working with high-energy devices, so safety should always be your top priority. Here are some essential safety precautions:

1. Avoid short circuits: Be very careful not to touch the positive and negative terminals together. This is especially important when using metal tools.

2. Use insulated tools: Whenever possible, use tools with insulated handles to reduce the risk of accidental shorts.

3. Work in a safe environment: Choose a clean, dry workspace free from flammable materials.

4. Wear safety gear: Consider using safety glasses and gloves to protect yourself.

5. Keep a fire extinguisher close by. If a battery fire happens, use a Class D fire extinguisher.

6. Never leave charging batteries unattended: Always monitor the charging process, especially during the first few cycles.