Nano LFP Cathodes: Powering Lithium-Ion Batteries in Extreme Cold

"Lithium-ion batteries traditionally struggle in subzero environments. Wiltson Energy has developed a nano-grade high-rate lithium iron phosphate (Nano LFP) cathode as a breakthrough solution. This paper outlines our innovative technology engineered to deliver stable performance where other batteries fail."

1. The Challenge: Battery Performance at Subzero

Operating lithium-ion batteries in freezing conditions is notoriously difficult. Electrochemical reactions slow dramatically, increasing internal resistance. Most cells experience a >40% drop in capacity by -20°C.

Kinetic Slowdown

Sharp capacity loss and voltage lag under load due to poor ionic diffusion and high impedance.

Lithium Plating Risk

Charging below 0°C can cause lithium metal plating on the anode, leading to permanent damage and safety hazards.

Electrolyte Limitations

Viscosity increases and ionic conductivity drops, exacerbating polarization.

Unpredictable Failure

Instability leads to erratic behavior or outright failure in critical cold-weather applications.

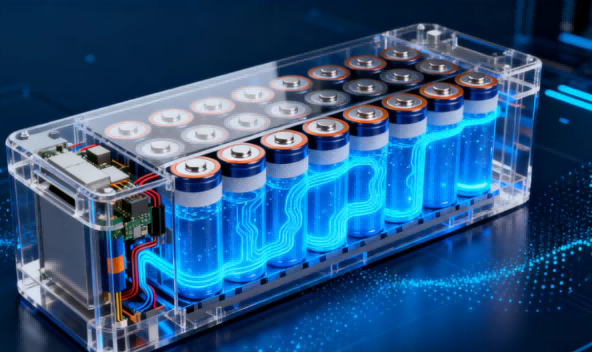

2. The Solution: Nano LFP Technology

Wiltson Energy’s nano-engineered cathode establishes a new benchmark for harsh climates, marrying the safety of LiFePO₄ with extreme cold performance.

Engineered for operation in deep freeze without external heating.

Supports discharge rates up to 7C even at -40°C.

Retains vast majority of capacity at -40°C (1C discharge).

Intrinsic safety meeting military-grade abuse standards.

3. Engineering & Synthesis

How do we achieve this? Through advanced structural engineering focusing on nanoscale features.

A Design Principles

- Nanoscale Crystallites: Small particle size dramatically shortens the Li⁺ ion diffusion path.

- Super 3D Conductive Networks: Ensures excellent electronic conductivity throughout the electrode.

- Synergistic Design: Paired with advanced hard carbon/graphite anodes to suppress lithium plating.

B Synthesis Methods

- Orthogonal Material Engineering: "Aligning" the cathode structure at the nano-scale.

- Conformal Carbon Coating: A nano-thick layer tuned to guarantee electrical contact.

- Automated Production: 30,000 m² facility with 95% automation ensuring industrial reliability.

4. Cycle Life & Reliability

A solution for extreme cold must endure. Nano LFP performs from Day 1 and continues for years.

Maintains integrity even when cycling between -20°C and -30°C.

Yields ≥90% of nominal capacity even at -40°C.

Wiltson Energy: Leading the Cold Revolution

By solving the core challenges of subzero temperatures, Wiltson opens new frontiers for reliable clean energy storage and electric mobility in cold regions.