LiFePO₄ Cathode and Low-Temperature Performance | How LFP Structure Limits Lithium-Ion Battery Capacity

The LiFePO4 (LFP) cathode material has a very high influence on the low-temperature discharge performance of lithium iron phosphate batteries. It is one of the dominant factors, accounting for an estimated 50–70% of the total impact. In other words, it is the main bottleneck limiting the low-temperature performance of LFP batteries.

1. Mechanism Analysis: Why Does LFP Perform Poorly at Low Temperatures?

LFP batteries experience a sharp drop in capacity at low temperatures, which mainly comes from the intrinsic physical and chemical properties of the LFP material itself.

-

1. Low Electronic and Ionic Conductivity

At room temperature, LFP's electronic conductivity is already low (~10-9 S/cm). Even after carbon coating, it only improves to about 10-1 S/cm—still much lower than materials like NMC. At low temperatures, electron hopping and migration become more difficult. This increases ohmic polarization and reduces the effective voltage platform.

-

2. One-Dimensional Ion Diffusion Channels

LFP has an olivine crystal structure, where lithium ions (Li+) can only diffuse through specific one-dimensional channels—a "single-lane road." At low temperatures, the thermal energy of lithium ions decreases. In these narrow 1D pathways, the activation energy for migration increases, and the diffusion rate drops dramatically, leading to strong concentration polarization. This is the most fundamental intrinsic limitation.

-

3. High Delithiation Energy Barrier

During charging, Li+ must overcome a relatively high energy barrier to leave the LiFePO4 lattice. At low temperatures, this process slows down significantly, limiting both charge acceptance and discharge capacity.

-

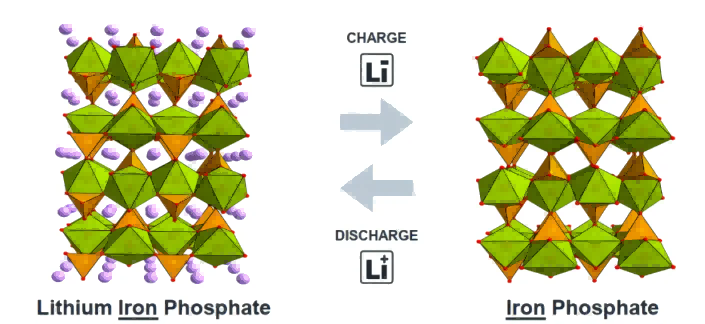

4. Two-Phase Reaction Mechanism

The charge/discharge process involves a two-phase transformation between LiFePO4 and FePO4. The nucleation and growth of the new phase slow down significantly at low temperatures, further reducing the reaction rate.

Simple Analogy:

At low temperatures, the LFP cathode is like a narrow, icy tunnel (the 1D diffusion channel). The “vehicles” (Li+ ions) lose power (thermal energy) and move slowly, causing a severe traffic jam (polarization), which drastically reduces the total throughput (discharge capacity).

2. Weight of Influence: Why Is LFP Responsible for 50–70%?

The battery's low-temperature performance is a system-level outcome, but the components' impact is not equal.

| Component | Estimated Weight | Description |

|---|---|---|

| Cathode (LFP) | ~50–70% | Dominant factor. Inherently low ionic/electronic conductivity and 1D diffusion pathway are the main physical reasons for poor low-temperature behavior. |

| Electrolyte | ~20–30% | Secondary factor. Viscosity increases and ionic conductivity reduces at low temperatures. Its effect is limited by the cathode's intrinsic functional ceiling. |

| Anode (Graphite) | ~10–20% | Graphite also faces slow Li+ diffusion and lithium plating, but the LFP cathode is typically the greater rate-limiting step in this chemistry. |

| Binders, Conductive Agents, etc. | <5% | Minor factors affecting electrode microstructure and interfacial resistance. |

Conclusion: A battery is like a wooden barrel; the shortest plank determines its total capacity. The LFP cathode is that shortest plank. Optimizing other components helps, but cannot overcome the LFP's intrinsic material limitations.

3. Improvement Strategies: Enhancing LFP Low-Temperature Performance

Since LFP is the main bottleneck, fundamental improvement efforts focus on modifying the material itself.

-

Particle Nanostructuring

Principle: Reducing LFP particle size to the nanoscale shortens the lithium-ion diffusion path and minimizes concentration polarization. This is the most direct and effective method.

-

Efficient Carbon Coating

Principle: A continuous, highly conductive carbon layer (e.g., graphene) provides fast electron pathways, improving conductivity and reducing ohmic polarization. Works best with nanostructuring.

-

Bulk Doping

Principle: Introducing dopant metal ions (e.g., Mg2+, Zr4+, V5+, Ti4+) into the LFP lattice can widen lithium diffusion channels or increase intrinsic electronic conductivity. This is an intrinsic structural modification.

-

Electrolyte Optimization

Supporting Role: Using low-viscosity solvents, new lithium salts, and SEI-forming additives can reduce liquid and interfacial resistance, helping Li+ reach the cathode surface more easily. Necessary but insufficient alone.

-

Full-Cell Engineering

Optimizing electrode thickness, compaction density, and separator thickness can reduce internal resistance from an engineering standpoint.

Summary

- Influence weight: The LiFePO4 cathode has a dominant effect on low-temperature performance (50–70%) due to its intrinsic low conductivity and one-dimensional Li+ diffusion path.

- Core issue: At low temperatures, Li+ diffusion within the LFP solid phase becomes the rate-determining step.

- Improvement direction: The fundamental approach is to modify the material itself (nanostructuring, coating, doping). Electrolyte and cell design are important supporting measures.

The electrode defines the upper limit of performance, and the electrolyte helps you reach it — not break it.